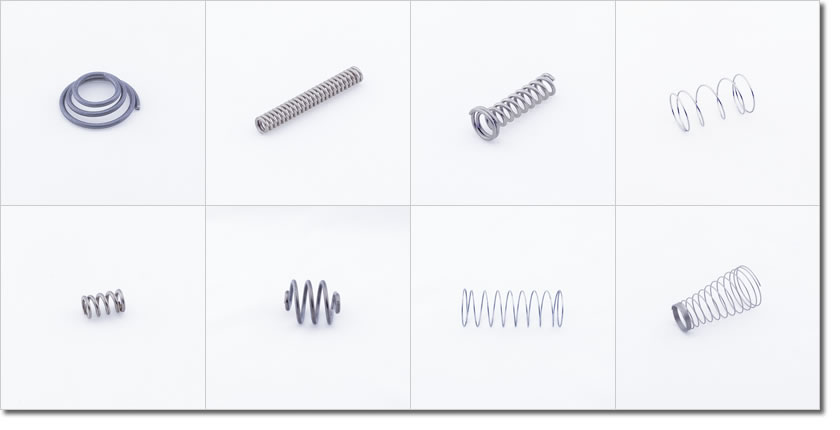

return springs - pressure-resilient coiled metal spring

Compression springs: Small springs with maximum effect

Probably the most popular form among the technical springs are the compression springs.

Everybody knows her. Compression springs became known above all through their use in the ballpoint pen.

Compression springs are used in almost all industrial sectors and in all sizes.

What initially gives the impression that they are a "simple" component, is developing often as a demanding task. Reiner Schmid Produktions GmbH has focused on the production of high quality compression springs specializes in this area and offers you a large selection of different sizes and designs. When manufacturing the compression springs, we will also be able to meet your wishes explicitly, so that the production of individual springs is possible for you.

Versatile options

The possibilities of compression springs can also be varied.

In the standard variant, compression springs consist of a cylindrical spring body of a spring wire in a certain wire thickness.

The spring body has a length (L0) and a certain diameter (Di, Da). The number of turns is usually defined as "total" (nt or ig) and "resilient" (n or if), where nt = n + 2. In the standard version have Compression springs so at each end a turn that is not rising, but created. Most of the time, compression springs become right Made around wrapped. Compression springs over a wire diameter of d = 1.0 are often ground at the spring ends, to create a flat support.

Grinding of compression springs

The production of compression springs, like the production of other springs, consists of several steps. An essential part of the production of compression springs is grinding. However, the grinding of the spring ends is a Cost and quality intensive process that is chosen wisely. With thinner wire thicknesses can mostly on the grinding the spring ends of the compression springs are omitted. Besides them, there are other versions of compression springs.

They include "conical" designs, in which the turns are not on "block" but on actuation. In addition, compression springs are offered as double-conical or barrel-shaped. Also compression springs with different pitch dimensions in the windings, as well as with several applied areas of the windings in the spring body are used. In rarer cases, compression springs are also made wound left. With us you get all types.

On request, we also take over special designs of compression springs for you. For the production of springs of all types and sizes, we rely on modern machinery.

This allows us to respond to your own wishes. Compression springs, like other technical springs, also have to be extra special be made precisely. In order for this to be possible, we carefully coordinate your wishes in advance with the possibilities. Thereby we guarantee optimal results.

Request a free quote now: Tel.: 004921238241873

Request a free quote by email now

Reiner Schmid Produktions GmbH Specialist and expert for the manufacture, production, production, development and sample production of torsion springs, double torsion springs and bent wire parts.

Abstract:

The manufacture, production and production of torsion springs, double torsion springs and bent wire parts is carried out in small series, large series and variant production.

The calculation, development and testing of torsion springs, double torsion springs and bent wire parts takes place before each production.

We offer customers a comprehensive application-related service such as advice, calculation, development and sample production for torsion springs, double torsion springs and bent wire parts.

Keywords:

torsion spring, torsion springs, double torsion spring, double torsion springs, bent wire part, bent wire parts

The torsion spring:

Cylindrical torsion springs or also known as torsion springs, helical torsion springs are widely used and versatile machine elements components in the world of mechanics and spring technology.

The structure of a cylindrical torsion spring consists of a wire that is wound in a helical shape around a central axis in even turns.

torsion springs are used to absorb and release a rotating movement, a torque or a force and to guide the movement of the legs.

torsion springs are characterized by the ability to absorb and release deflections, forces or torques around a rotation axis and to guide the rotational movement.

torsion springs usually have a cylindrical spring body on which two legs are arranged.

The legs can be arranged tangentially, radially or axially, whereby each leg can have a different arrangement. Different spring end shapes can be attached to the end of the two legs, e.g. straight leg, hook shape, eyelet shape, round or square.

The terms "torsion spring", "torsion spring" and "torsion spring" refer to the same component.

More detailed information about torsion springs, torsion springs, torsion springs - torsionally resilient wound metal spring ...

The double torsion spring:

Double torsion springs, double torsion springs and double torsion springs are widely used and versatile machine elements in the world of mechanics and spring technology.

The structure of a double torsion spring consists of a wire that is wound in a helical shape in even turns to form two separate spring bodies. The two spring bodies are connected by a wire, which is usually designed as a U-shaped web.

The legs or spring ends of the double torsion springs are usually attached to the outside of the respective spring body. The force or torque is introduced either via the U-shaped web or via the legs. The double torsion spring is usually guided via a mandrel, axle or bolt.

Double torsion springs, double torsion springs and double torsion springs are used to absorb or release a rotating movement, torque or force. Double torsion springs are characterized by the ability to absorb or release deflections, forces or torques around a rotation axis. The legs can be arranged tangentially, radially or axially, whereby each leg can have a different arrangement. Different spring end shapes can be attached to the end of the two legs, e.g. straight leg, hook shape, eyelet shape, round or square.

More detailed information on double torsion springs, double torsion springs and double torsion springs ...

The wire bent part:

In practical use, standardized wire bent parts such as spring rings, snap rings, retaining rings, clips, pins, etc. are found. A paper clip or a staple clip also belongs to the wire bent parts, wire form springs and bent parts.

However, in practical use, non-standardized, individual, application-specific designed wire bent parts are mostly used. Wire form springs and bent parts are used.

The focus is on the function of the component: e.g. securing, protecting, holding, positioning, clamping or springing.

Wire form springs, wire form springs and bent parts made of spring steel wire are important components in various industries and applications. Bent wire parts are special machine elements that usually have springy properties.

They are made into a specific shape by bending wire and offer a variety of advantages in terms of flexibility, cost-effectiveness and functionality.

More detailed information on bent wire parts, wire form springs and bent parts ...